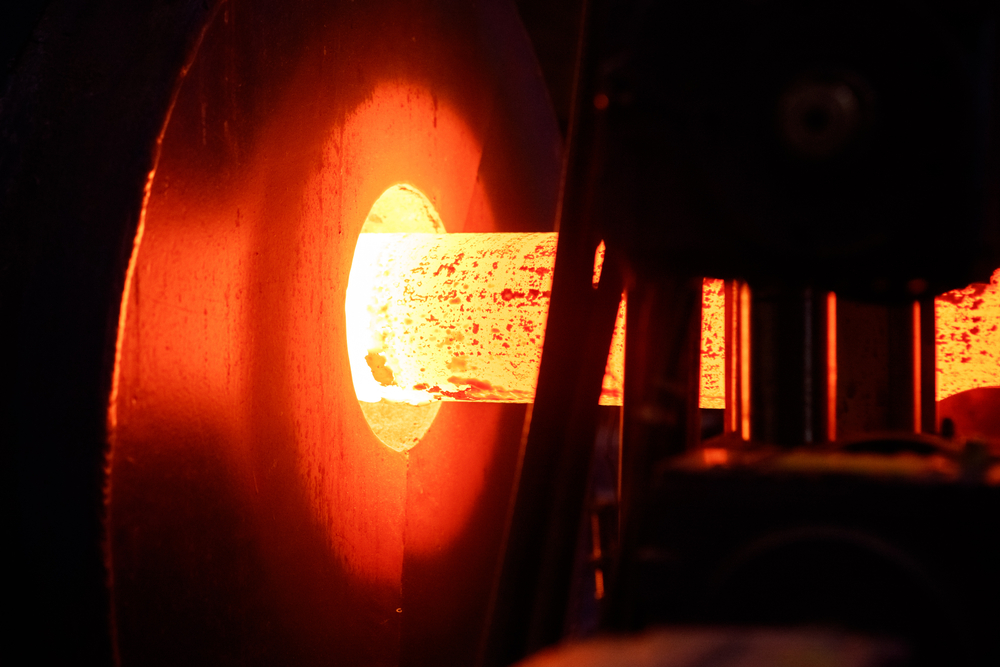

How to Measure IGBT Current in Induction Heating?

Induction heating is a widely used process in various industries to heat metals and other materials quickly and efficiently. One crucial aspect of induction heating is the measurement of IGBT (Insulated Gate Bipolar Transistor) current, as it plays a significant role in controlling the power output and efficiency of the induction heating system. This blog will discuss how to measure IGBT current in induction heating, the importance of accurate current measurement, and the different methods available for measuring IGBT current.

Importance of Accurate IGBT Current Measurement

Measuring IGBT current in an induction heating system is essential for several reasons. First and foremost, accurate current measurement ensures that the system operates within safe operating limits. If the current exceeds the IGBT’s rated value, it can lead to overheating and potentially damage the IGBT, resulting in system downtime and costly repairs.

Furthermore, measuring IGBT current allows for the optimization of the system’s performance. By monitoring the current, operators can identify any issues or abnormalities in the system and make adjustments to improve efficiency and productivity. Additionally, accurate current measurement enables the system to maintain consistent heating levels, resulting in high-quality finished products.

Methods of Measuring IGBT Current

Several methods are available for measuring IGBT current in an induction heating system. The most common methods include:

- Current Transformers: Current transformers are widely used for measuring AC current in electrical systems, including induction heating systems. These devices work by inducing a secondary current proportional to the primary current passing through the IGBT. Current transformers are highly accurate and can provide real-time measurements of IGBT current.

- Hall Effect Sensors: Hall Effect sensors are another popular method for measuring IGBT current. These sensors work based on the Hall Effect, which generates a voltage proportional to the magnetic field created by the current passing through the IGBT. Hall Effect sensors are non-invasive and can provide accurate measurements of DC and AC currents.

- Shunt Resistors: Shunt resistors are precision resistors placed in series with the IGBT to measure the voltage drop across the resistor, which is proportional to the current passing through the IGBT. Shunt resistors are cost-effective and easy to implement but may require calibration to ensure accurate measurements.

- Rogowski Coils: Rogowski coils are flexible current sensors that work based on Faraday’s law of electromagnetic induction. These coils can measure AC and DC current and are ideal for applications where space is limited or high-frequency current measurements are required.

Choosing the right method for measuring IGBT current depends on factors such as the type of induction heating system, the required accuracy of the measurements, and budget constraints. It is essential to consult with a qualified technician or engineer to determine the most suitable method for your specific application.

Tips for Accurate IGBT Current Measurement

To ensure accurate IGBT current measurement in an induction heating system, follow these tips:

- Calibrate the measuring device regularly to maintain accuracy and reliability.

- Use high-quality measuring instruments and sensors to minimize errors and ensure consistent results.

- Implement proper grounding and shielding techniques to reduce electromagnetic interference and improve measurement accuracy.

- Monitor the current continuously and look for any fluctuations or abnormalities that may indicate a problem with the IGBT or the induction heating system.

- Consult with experts in induction heating technology for guidance on selecting the appropriate measuring method and interpreting the results accurately.

Contact Mend Tech Inc. Today

As a leading manufacturing and production company specializing in induction heating technology, Mend Tech Inc. is committed to delivering top-quality products and services to our customers. With our expertise and experience in the industry, we can help you optimize your induction heating system’s performance by providing accurate IGBT current measurement solutions.

Whether you need assistance with measuring IGBT current, troubleshooting system issues, or upgrading your induction heating equipment, Mend Tech Inc. is here to help. Contact us today to learn more about our services and how we can support your manufacturing operations.

At Mend Tech Inc., we strive to exceed our customers’ expectations and provide unparalleled support to help you achieve your production goals. Trust us to be your trusted partner in the industry and experience the difference of working with a premier manufacturing company dedicated to excellence. Contact Mend Tech Inc. today and take your induction heating system to the next level.