How Does Induction Heating Work?

Induction heating is a fascinating technology that has revolutionized the manufacturing and production industry. Elective heating offers numerous advantages over traditional heating methods, such as flames or conduction, by utilizing electromagnetic induction to heat materials. This blog will explore how induction heating works, its applications, and its benefits in various industries.

What is Induction Heating?

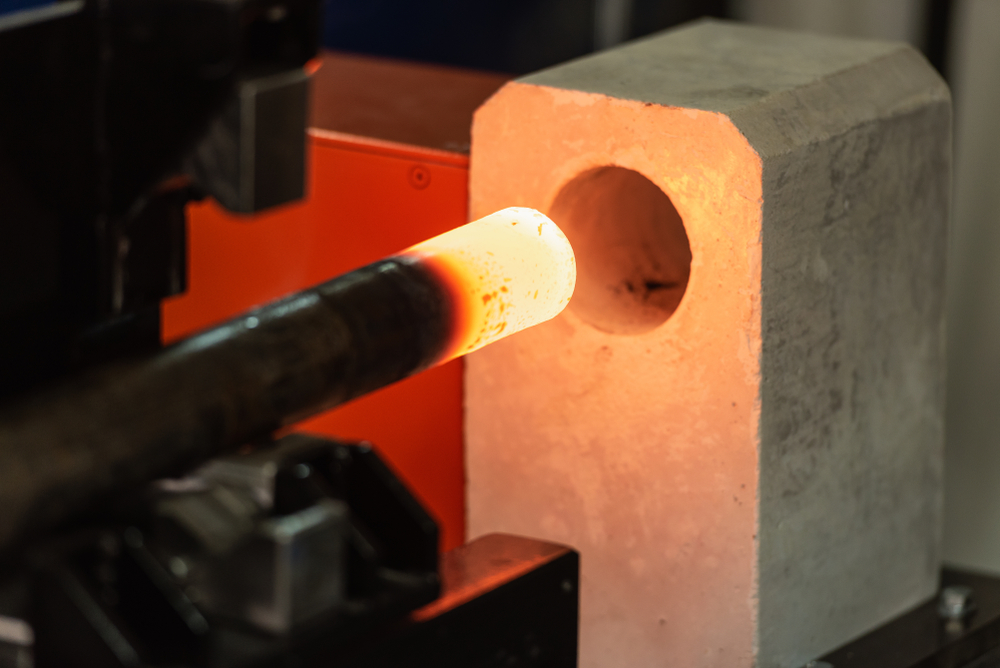

Induction heating is a process where an alternating magnetic field is used to generate heat within a conductive material. The induction coil, also known as the inductor, creates a high-frequency electromagnetic field that induces currents in the metal workpiece. These currents flow through the resistance of the material, generating heat in the process. Unlike traditional heating methods that rely on external heat sources, induction heating heats the material internally, resulting in faster and more efficient heating.

How Does Induction Heating Work?

The induction heating process begins with the induction coil, which is typically made of copper or other conductive materials. When an alternating current passes through the coil, it creates a rapidly changing magnetic field around it. When this magnetic field encounters a conductive material such as metal, it induces electrical currents within the material.

These induced currents flow through the resistance of the material, generating heat due to the Joule effect. The heat is produced directly within the material, allowing for precise control over the heating process. By adjusting the frequency and power of the alternating current, manufacturers can control the temperature and speed of heating, making induction heating ideal for a wide range of applications.

Applications of Induction Heating

Induction heating is widely used in various industries for a multitude of applications. Some common uses of induction heating include:

- Brazing and soldering: Induction heating is commonly used for brazing and soldering applications in the automotive, aerospace, and electronics industries. The precise control over temperature and heating time makes induction heating ideal for joining components with high precision and efficiency.

- Heat treatment: Induction heating is also used for heat-treating processes such as hardening, tempering, and annealing. Manufacturers can alter the material’s properties, such as hardness and strength, by heating it to specific temperatures and then cooling it rapidly.

- Melting and casting: Induction heating is commonly used for melting and casting metals such as steel, aluminum, and copper. The high temperatures generated by induction heating allow for rapid and efficient melting of metals, making it a popular choice for foundries and metal processing plants.

- Welding: Induction heating is used in various welding applications, including seam welding, tube welding, and blade welding. The fast and localized heating provided by induction heating allows for precise control over the welding process, resulting in high-quality welds with minimal distortion.

Benefits of Induction Heating

There are numerous benefits to using induction heating in manufacturing and production processes. Some of the key advantages of induction heating include:

- Efficient heating: Induction heating heats the material directly, resulting in faster heating times and lower energy consumption compared to traditional heating methods.

- Precise control: Manufacturers can control the temperature, heating time, and heating patterns with precision, allowing for consistent results and high-quality products.

- Clean and safe: Induction heating does not require open flames or hot surfaces, making it a cleaner and safer heating method for workers and the environment.

- Versatility: Induction heating can be used for a wide range of materials, shapes, and sizes, making it a versatile heating method for various applications.

Contact Mend Tech Inc. Today

At Mend Tech Inc., we specialize in providing high-quality manufacturing and production services using cutting-edge technologies such as induction heating. With our state-of-the-art facilities and experienced team of engineers, we can help you meet your production needs efficiently and effectively.

Whether you need custom metal fabrication, heat treating, brazing, or welding services, Mend Tech Inc. has the expertise and capabilities to deliver top-quality products that meet your specifications. Contact us today to learn more about our services and how we can help you achieve your manufacturing goals.

Induction heating is a powerful technology that offers numerous benefits for the manufacturing and production industry. Manufacturers can leverage this technology to improve efficiency, quality, and safety in their processes by understanding how induction heating works and its applications. Contact Mend Tech Inc. today to learn more about our services and how we can help you with your manufacturing needs.