What Metals Can Be Melted in an Induction Furnace?

Induction melting furnaces have become an integral part of many manufacturing processes due to their efficiency and precision in melting various metals. These furnaces use electromagnetic induction to heat and melt metals quickly and uniformly, making them ideal for a wide range of applications. If you are considering investing in an induction furnace for your manufacturing operations, it is essential to understand what metals can be melted in these powerful machines.

Overview of Induction Furnaces

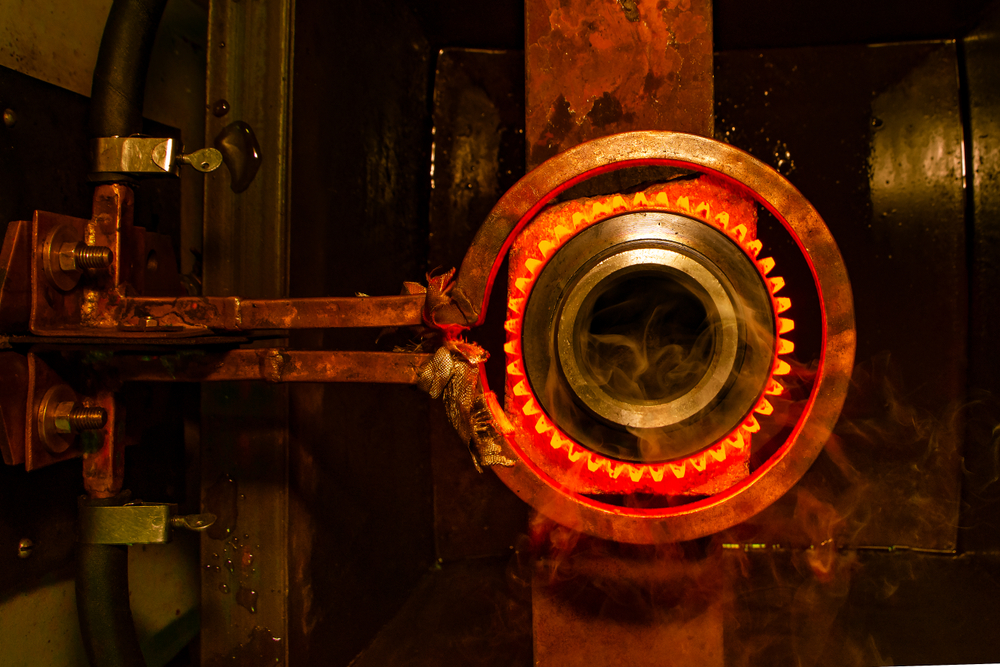

Induction furnaces work on the principle of electromagnetic induction, where an alternating current passes through a copper coil, creating a magnetic field. When a metal object is placed within this magnetic field, it induces eddy currents that generate heat within the metal, causing it to melt. This process ensures quick and efficient melting of metals without direct contact between the heating element and the metal.

Induction furnaces come in various sizes and configurations, from small benchtop models to large industrial-sized units capable of simultaneously melting several tons of metal. These furnaces are commonly used in foundries, metal casting facilities, and other manufacturing industries where precise control over melting temperatures is essential.

Metals Suitable for Induction Melting

While induction furnaces are versatile and can handle a wide range of metals, some are more commonly melted using this technology due to their specific properties and applications. Some of the metals that can be melted in an induction furnace include:

Steel

Steel is a common metal melted in induction furnaces due to its widespread use in various industries, including automotive, construction, and manufacturing. Induction furnaces can melt carbon steel and alloy steel, allowing manufacturers to create custom blends and alloys as needed.

Cast Iron

Cast iron is another metal that is well-suited for induction melting. Its high carbon content and ability to flow easily when molten make it a preferred choice for applications requiring intricate shapes or high strength. Induction furnaces can melt both gray cast iron and ductile iron, allowing manufacturers to produce a wide range of cast iron components.

Copper

Copper is a highly conductive metal that is commonly melted using induction furnaces. Its excellent electrical and thermal properties make it ideal for electronics, telecommunications, and power generation applications. Induction furnaces can accurately control the melting temperature of copper, ensuring high-quality molten metal for casting or forging processes.

Aluminum

Aluminum is a lightweight and corrosion-resistant metal widely used in aerospace, automotive, and construction industries. Induction furnaces can melt both pure aluminum and aluminum alloys, offering manufacturers precise control over the melting process to achieve the desired properties in the final product.

Precious Metals

Precious metals like gold, silver, and platinum are often melted using induction furnaces due to their high value and purity requirements. These metals are used in jewelry making, electronics manufacturing, and other high-end applications where quality and precision are paramount. Induction furnaces can maintain the exact melting temperatures required for these metals, ensuring a clean and uniform melt every time.

Considerations for Induction Furnace Selection

When choosing an induction furnace for melting specific metals, several factors must be considered to ensure optimal performance and efficiency. Some key considerations include:

- Melting Capacity: Determine the amount of metal you will be melting on a regular basis to select a furnace with the right capacity for your production needs.

- Melting Temperature: Different metals have varying melting points, so choosing a furnace that can reach and maintain the required temperature for the metal you are working with is essential.

- Energy Efficiency: Induction furnaces are known for their energy efficiency compared to traditional furnace technologies. Look for a furnace that is designed to minimize heat loss and maximize melting efficiency.

- Control Systems: Modern induction furnaces come equipped with advanced control systems that allow for precise temperature regulation and melting process monitoring. Choose a furnace with user-friendly controls that meet your specific requirements.

- Safety Features: Safety is a top priority in any manufacturing operation. Select an induction furnace with built-in safety features like temperature sensors, emergency stop buttons, and overheat protection to ensure a secure working environment.

Mend Tech Inc.: Your Trusted Partner for Induction Furnaces

At Mend Tech Inc., we understand the importance of having reliable and efficient induction furnaces for your manufacturing operations. As a premier manufacturing and production company based in Garfield, NJ, we take pride in designing and producing top-quality induction furnaces that meet the specific needs of our clients. Whether you require a standard furnace for melting steel or a customized solution for melting precious metals, our team of skilled professionals is dedicated to delivering exceptional results that exceed your expectations.

With our commitment to excellence and innovation, Mend Tech Inc. has established itself as a trusted provider in the industry, offering a range of induction furnaces that are designed for precision, efficiency, and durability. Our extensive experience in the field of induction melting furnaces allows us to tailor our solutions to your unique requirements, ensuring that you get the right furnace for your specific applications.

Contact Us Today

Induction furnaces are versatile and efficient tools for melting a wide range of metals, from steel and cast iron to copper, aluminum, and precious metals. By understanding the properties of different metals and the capabilities of induction melting technology, manufacturers can make informed decisions when selecting the right furnace for their specific needs. Whether you want to upgrade your melting equipment or invest in a new furnace for your manufacturing operations, Mend Tech Inc. is here to help.

If you are ready to take your metal melting capabilities to the next level, contact Mend Tech Inc. today to learn more about our induction furnace solutions. With our expertise and dedication to quality, we can provide you with the perfect furnace that meets your requirements and exceeds your expectations. Explore our range of induction furnaces and discover how we can help enhance your manufacturing processes.